In early June, maPlatine.com was invited by REGA to visit the production site of vinyl turntables, cartridges and other electronic products from the leading High Fidelity brand.

Tour of REGA’s plant

The visit of REGA’s production facilities was hosted by founder Roy Gandy in person and Guy Boselli, the French importer from Sound & Colors. The British firm greeted us with the French flag! This was a great heart-warming surprise.

Production of REGA vinyl turntables

Naturally, we couldn’t go to REGA without finding out how their record players are made! We had the opportunity to see how the new Planar 2 vinyl turntables are built. We saw EVERYTHING, from assembly to quality testing! =)  Each element of the vinyl turntable is made, mounted and assembled by hand! In regards to the plinths, they are built meticulously and checked manually by REGA’s experts. They check that they comply with the quality charter. After the finishing polishing process, REGA employees assemble the motor and start more test phases.

Each element of the vinyl turntable is made, mounted and assembled by hand! In regards to the plinths, they are built meticulously and checked manually by REGA’s experts. They check that they comply with the quality charter. After the finishing polishing process, REGA employees assemble the motor and start more test phases.

Production of REGA tonearms

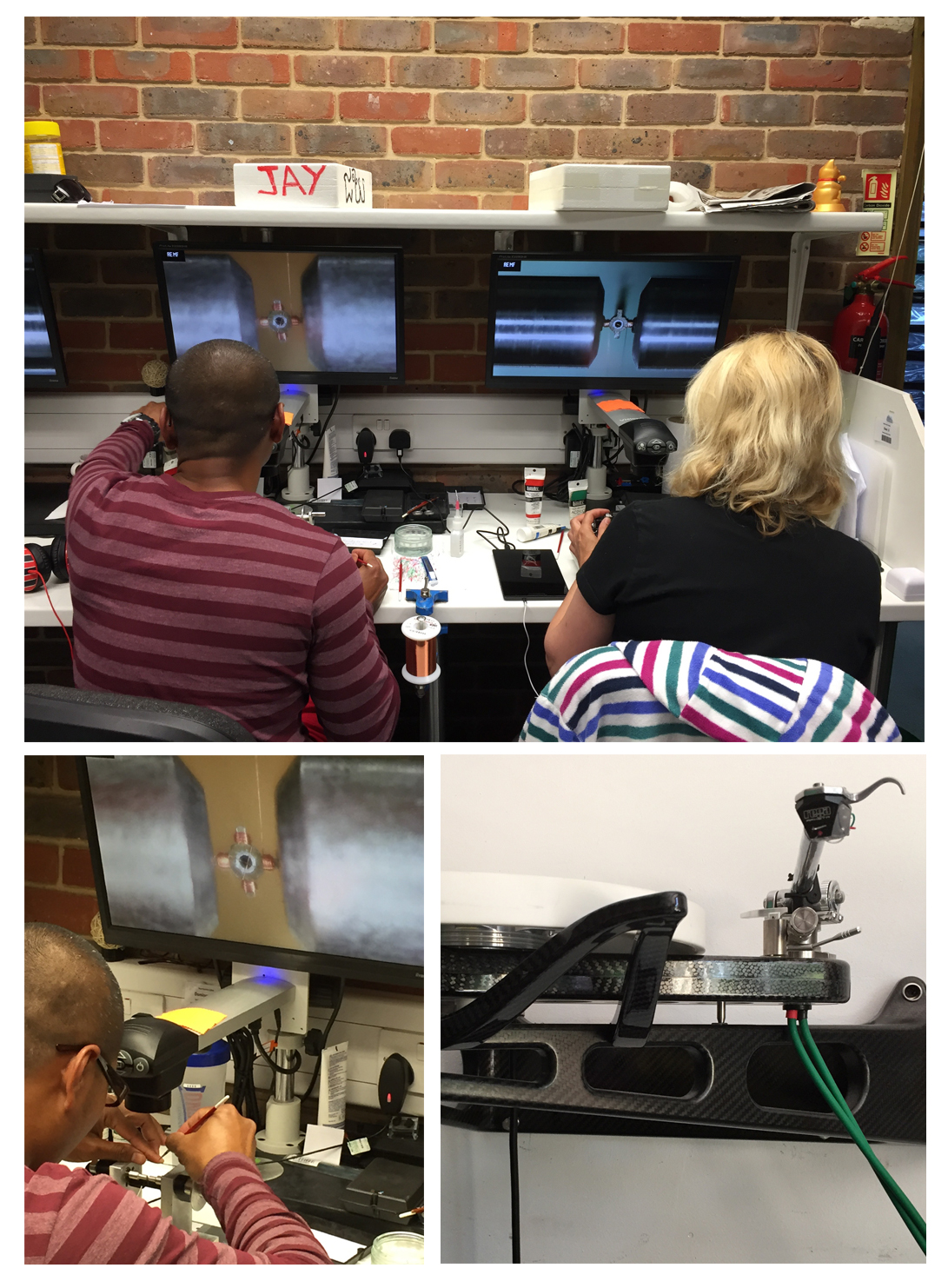

During our visit, we saw all the production processes for the various products from REGA. Below is how REGA tonearms are made. Tonearm wiring, check of its adjustment, machining and final assembly. All REGA tonearms for vinyl turntables are entirely hand-assembled! True precision work.  We were very impressed, especially by the bearing adjustment process that calls for true expertise. First of all, the technician checks the bearing for tightness, which enables them to check that there is no play when crimping the tonearm to the bearing. Then, the bearing’s buoyancy has to be confirmed, in other words, it must not be too rigid. All these operations are done by hand and require extensive expertise and great skill. The tonearms are also mounted and wired by hand, then they are mounted one by one by hand onto each vinyl turntable. We were stunned by the level of expertise and know-how required to perform all these tasks.

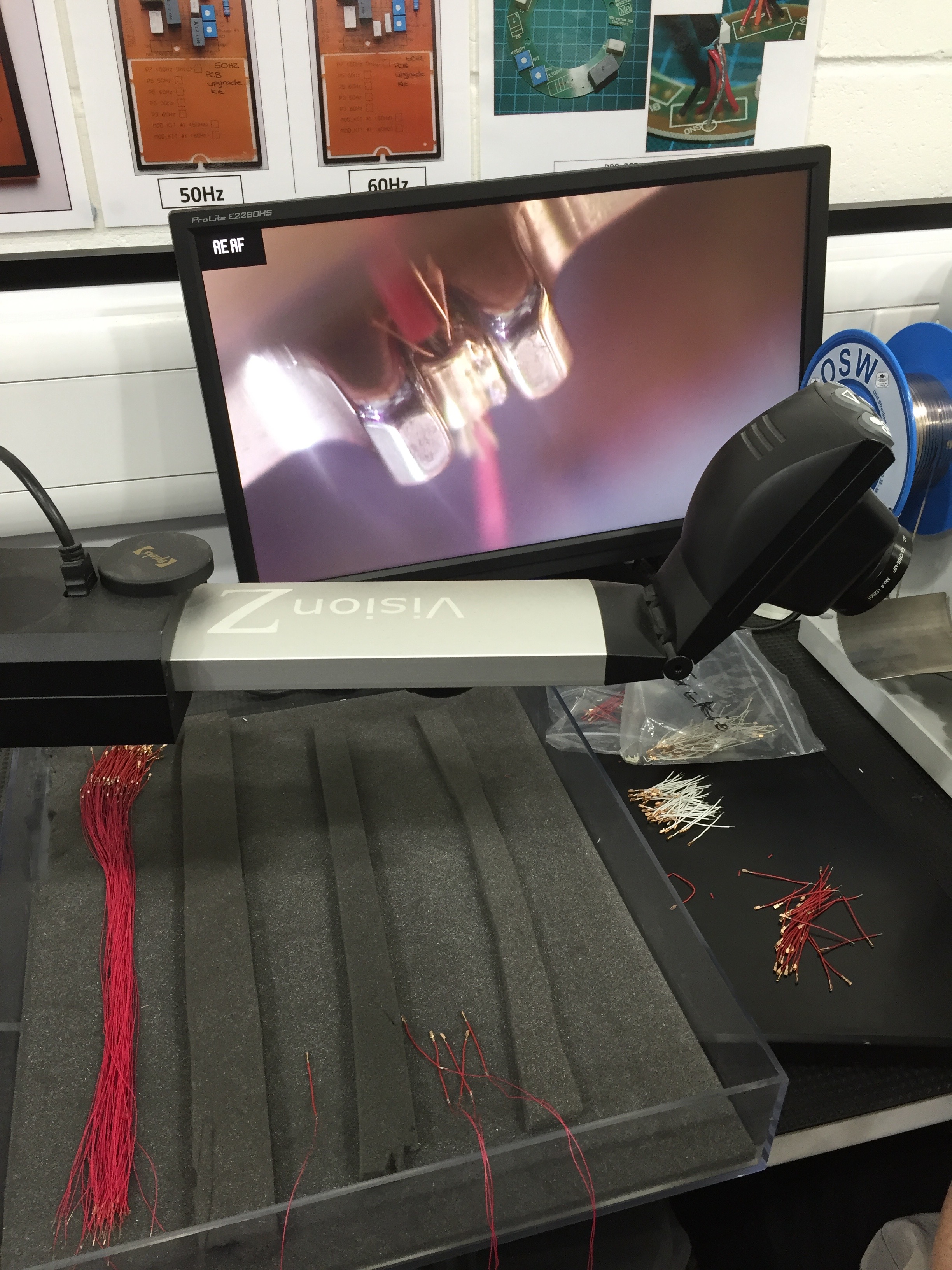

We were very impressed, especially by the bearing adjustment process that calls for true expertise. First of all, the technician checks the bearing for tightness, which enables them to check that there is no play when crimping the tonearm to the bearing. Then, the bearing’s buoyancy has to be confirmed, in other words, it must not be too rigid. All these operations are done by hand and require extensive expertise and great skill. The tonearms are also mounted and wired by hand, then they are mounted one by one by hand onto each vinyl turntable. We were stunned by the level of expertise and know-how required to perform all these tasks.  Above is an example of the modernity of the equipment used by REGA for tasks that require great precision. So all the production stages that require a microscope for very fine operations, REGA uses a macroscopic camera. Here, the technician is crimping the tonearm leads to the connectors that will then be plugged to the phono cartridge. We will review further down in the article the use of macro cameras, especially for winding the cartridges. Once mounted, REGA tonearms undergo a series of tests to check the product’s conformity to the brand’s requirements: the experts naturally check the production quality and that the product is perfectly mounted and set up. The adjustment phase is key to REGA‘s production process and quality charter.

Above is an example of the modernity of the equipment used by REGA for tasks that require great precision. So all the production stages that require a microscope for very fine operations, REGA uses a macroscopic camera. Here, the technician is crimping the tonearm leads to the connectors that will then be plugged to the phono cartridge. We will review further down in the article the use of macro cameras, especially for winding the cartridges. Once mounted, REGA tonearms undergo a series of tests to check the product’s conformity to the brand’s requirements: the experts naturally check the production quality and that the product is perfectly mounted and set up. The adjustment phase is key to REGA‘s production process and quality charter.  REGA’s tonearm experts are easy to spot… 😉

REGA’s tonearm experts are easy to spot… 😉

Production of REGA cartridges

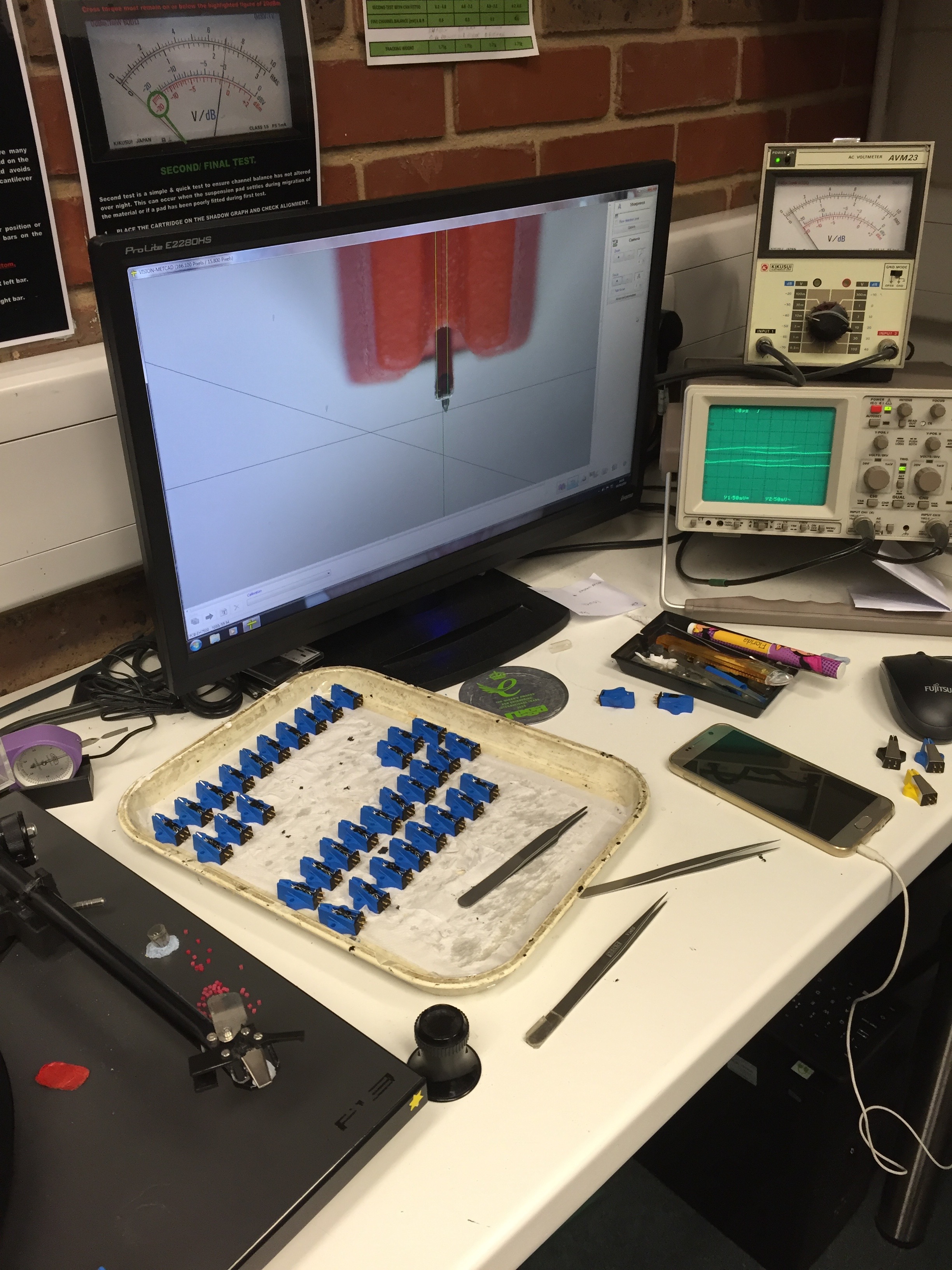

When we were shown into the workshop where REGA produces its cartridges, we were amazed by the work of one of the employees and the high precision equipment they use. The wires around the coils are thinner than hair, so they are almost invisible to the naked eye and extremely fragile. Below is the coil winding of high-end REGA MC cartridges (REGA Apheta MC cartridge, REGA Aphelion MC cartridge). Here also, macro cameras are used for this high precision work.  In regards to REGA’s MM cartridges, they also have to meet exacting quality standards.

In regards to REGA’s MM cartridges, they also have to meet exacting quality standards.  Once REGA’s cartridge are made, they all undergo drastic testing to check that the stylus is perfectly aligned. There is a macro camera connected to computer-aided software that makes for extreme accuracy for the quality checks.

Once REGA’s cartridge are made, they all undergo drastic testing to check that the stylus is perfectly aligned. There is a macro camera connected to computer-aided software that makes for extreme accuracy for the quality checks.

Polishing of production parts

For those of you who are wondering, all the small workpieces are polished with an eco-friendly process! They are processed through a machine with coarser grain and then with finer grain.

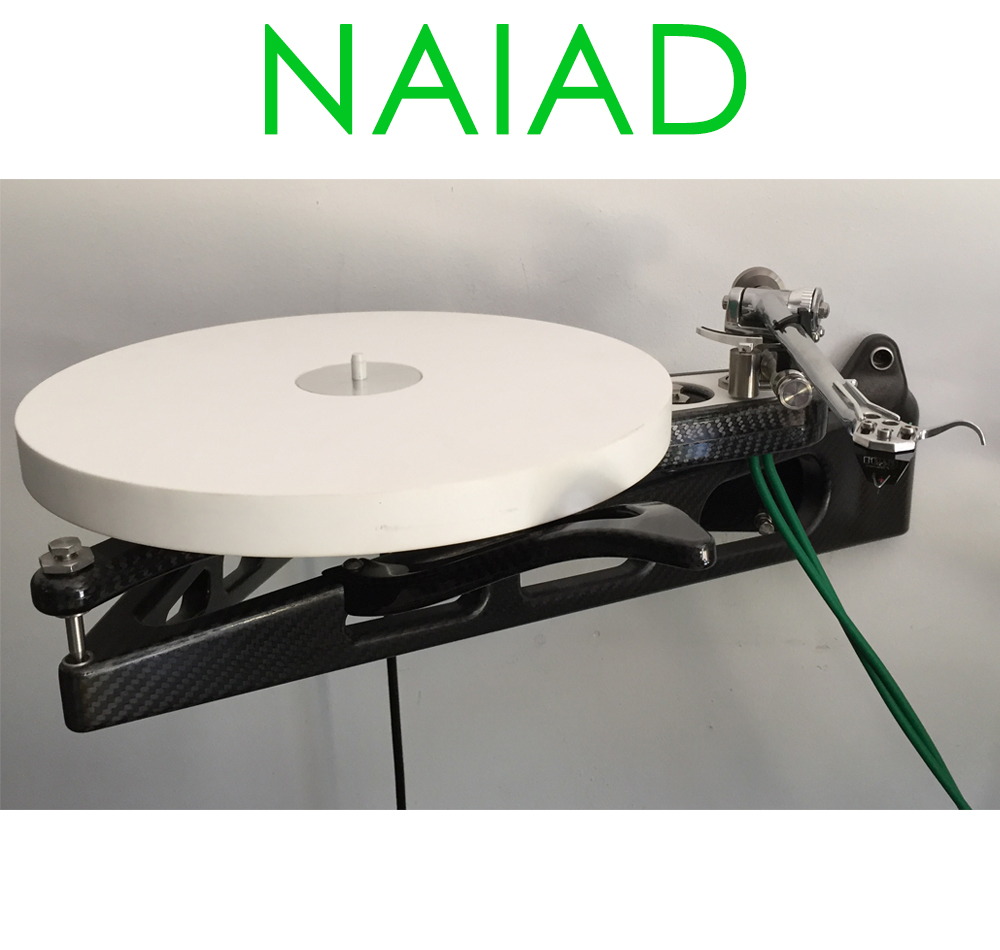

THE REGA NAIAD VINYL TURNTABLE

If you like to keep up to speed with REGA’s events or if you have read our interview of Roy Gandy, then you’ll know that the British brand has been working on a very exclusive turntable for a number of years: the REGA NAIAD. While we were on site, we had the chance to catch a glimpse of one of the very first prototypes of the NAIAD vinyl turntable! Here is a little overview…  The NAIAD is not just a great product, this turntable has also been a source of inspiration and innovation for record players currently on the market and for all of REGA’s lines (REGA RP1 vinyl turntable, the RP3, the RP6, the Planar 2, Planar 3…)

The NAIAD is not just a great product, this turntable has also been a source of inspiration and innovation for record players currently on the market and for all of REGA’s lines (REGA RP1 vinyl turntable, the RP3, the RP6, the Planar 2, Planar 3…)

****

A big thank you to Roy Gandy, founder of REGA, and Guy Boselli, the French importer for Sound & Colors, for having us and for your warm welcome!  Please feel free to read our blog article on the manufacturing processes of REGA’s CD players and amplifiers on our second website maChaineHiFi.com. Also watch our video about the visit:

Please feel free to read our blog article on the manufacturing processes of REGA’s CD players and amplifiers on our second website maChaineHiFi.com. Also watch our video about the visit: